AKVA group has sold feed barges for more than NOK 100 million the last month. Eidsfjord Sjøfarm has acquired an AC600PV feed barge with a flat roof - tailored for the company's toughest locations. In addition, AKVA group has sold three feed barges of the new AM5-Series to another customer.

This is Eidsfjord Sjøfarm's fifth AC600PV feed barge with v-bow from AKVA group. The feed barge has a v-shaped hull with a large bilge keel to withstand rough seas from all sides without compromising on stability. It is certified for a significant wave height of 5.5 and the feed storage capacity is 600 tonnes. The 8 feeding lines can be placed both in the bow or out on the port side.

“We are very satisfied with the v-bow solution from AKVA group. We need feed barges that are stable in rough waters and that have flexible feeding solutions, and AKVA group has proven to be a reliable supplier for several years. The new feed barge will be placed in our roughest location, and we look forward to getting it up and running,” says Roger Simonsen, General Manager of Eidsfjord Sjøfarm.

Due to the strong forces that are at play at the location, it is possible to feed from both the v-bow as well as from the side for better flexibility. This specific barge model was first developed in collaboration with Eidsfjord Sjøfarm, and is adapted to the rough conditions at their locations in Northern Norway with a flat roof without a wheelhouse.

“We are proud to be able to deliver innovative products in close collaboration with our customers. Eidsfjord Sjøfarm had location-specific needs, and together we found the right solution. We would like to thank Eidsfjord Sjøfarm for a good collaboration,” says Hans-Øyvind Sagen, Sales Director AKVA group Nordic.

Weather-proof

All four feed barges sold is special adapted for exposed locations with a significant wave height of 5.0 to 5.5 meters. Single waves of up to 11 meters can occur in such locations. In recent years, AKVA group has developed feed barge models in steel that can withstand very rough weather. AKVA group has previously delivered the gigantic AC800PVDB feed barge which can withstand significant wave heights of 7.5 meters.

“Several of our robust feed barges have not initially been bought to be used at exposed locations from day one. Our steel feed barge models are easy to move, and thus, fish farmers easily can move these feed barges to other locations with rougher conditions if this becomes relevant in the future. This is future-oriented thinking,” says Sagen.

New model

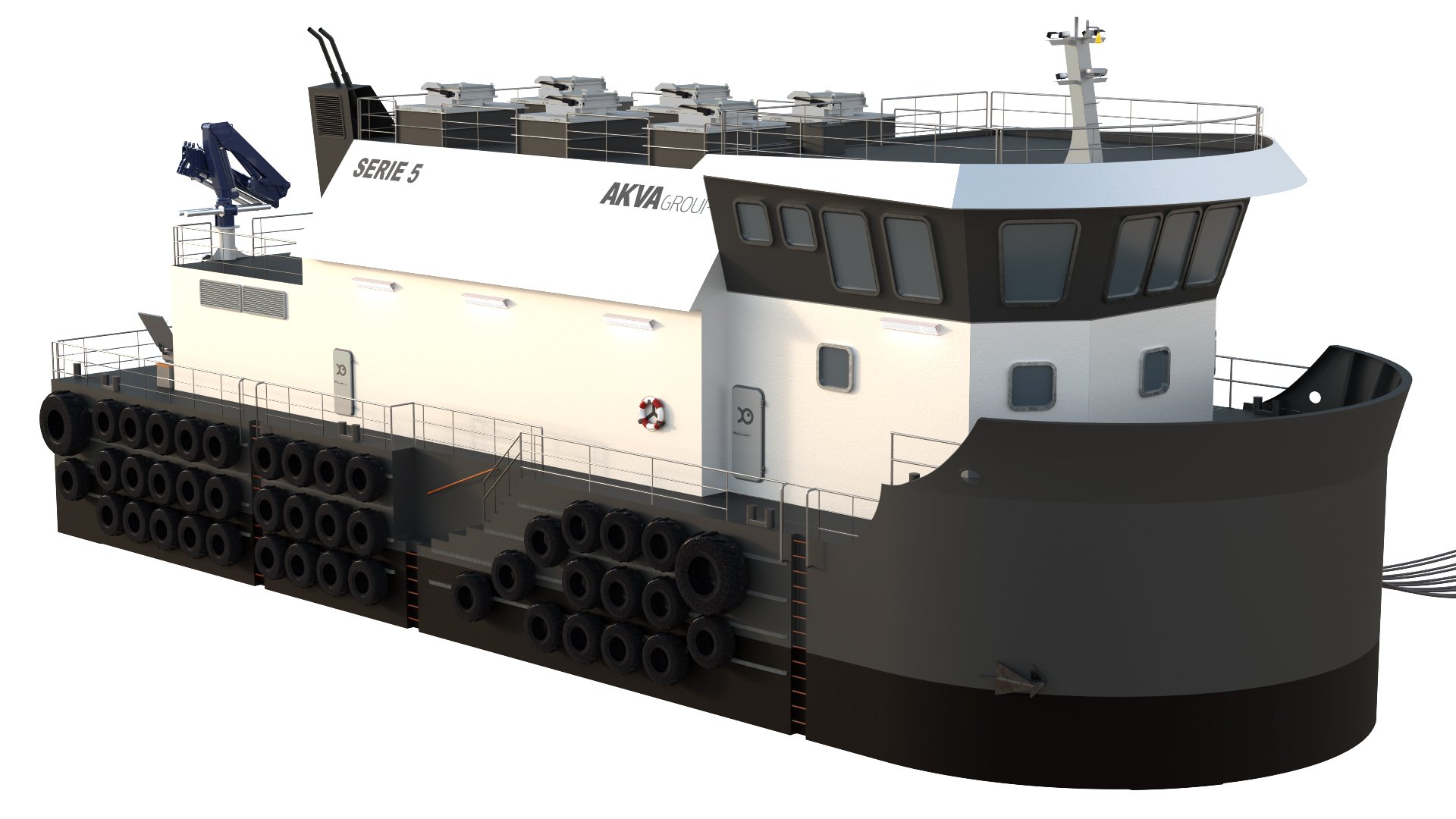

The other three feed barges sold in the last month are of the AM5-Series model.

“This is the very latest feed barge model from AKVA group. This model has a feed load capacity of 600 tonnes, 6 silos and 8 feeding lines that combine feeding from two silos each. This feed barge series is module-based so that it can also be offered with 4 or 8 silos, then this will be either AM3-Series or AM7-Series. The Series will range from about 360 - 750 tonnes and will be prepared for all our feeding systems,” says Sagen.

This way of designing the feed barges is also done to benefit customers.

“It is easier to optimize the production of different sizes of feed barge models and still have much of the same equipment and design on all models. This provides a price gain or efficiency gain for the customer,” says Sagen.

Exciting Q3

The three AM5 feed barges have a construction with a round bow and the feed barge can be upgraded up to significant wave heights of 5.5 meters. The feed barges are also equipped with a hybrid battery package, AKVA Hybrid, which makes them more environmentally friendly and energy-efficient. The combination of battery operation and diesel generator reduces the total energy consumption and saves cost.

“Cost-effective feeding was the keyword during the development of the AM3, AM5 and AM7 Series. We aim to deliver comprehensive solutions that combine hardware such as. new, efficient feed barge models, service solutions and good digital solutions so that feeding becomes more efficient and the total costs are reduced,” says Sagen.

He is looking forward to an exciting fall after a good summer.

“We are in dialogue with several forward-looking fish farming companies that are considering comprehensive solutions, precision farming and cost-effective operations in focus, says Sagen.