SinkabergHansen is investing in a new type of feeding technology that can provide major environmental effects and cost savings in the aquaculture industry. "We have got an efficient feeding machine," says Svein-Gustav Sinkaberg, CEO of SinkabergHansen.

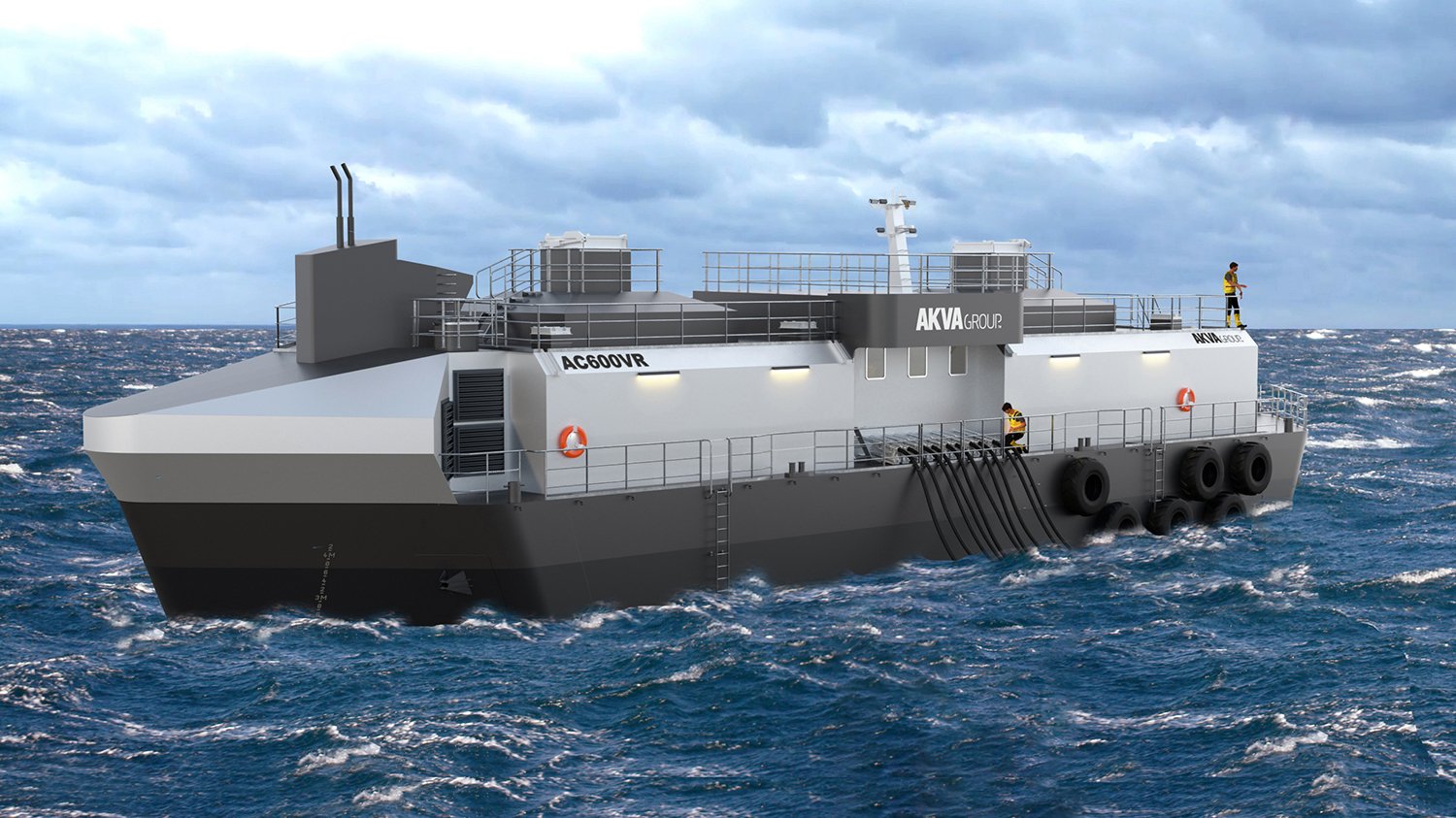

FEED BARGE WITH WATERBORNE FEEDING: SinkabergHansen has acquired an AC 600 VR feed barge with waterborne feeding to use at one of their most exposed locations. The new ten-line feeding system showed a 70-90 per cent reduction in the energy requirement, is very quiet in operation and is more environmentally friendly than traditional air feeding.

SinkabergHansen has purchased an AC 600 VR feed barge with new technology for waterborne feeding from AKVA group. The feed barge model has been developed for exposed locations and was first presented during Aqua Nor 2019.

"The feed barge with a waterborne feeding system can now be described as an efficient feeding machine. The environmental and cost benefits of waterborne feeding are so great that we see it as justifiable to invest in this type of feeding technology," says CEO Svein-Gustav Sinkaberg in SinkabergHansen.

SinkabergHansen will use the feed barge at the location Otervika - which is one of the company's most exposed locations.

Great savings

Great savings

Tests carried out during the development of the new ten-line feeding system showed a 70-90 per cent reduction in the energy requirement of feeding by waterborne feeding compared to air feeding. Waterborne feeding is also very quiet in operation, and microplastic wear inside feed hoses is not a problem with water transport.

"Waterborne feeding also provides good conditions for deep feeding. In addition to lower lice pressure at depth, there are several types of solutions we continue to work on to facilitate good fish welfare and good growth during deep operation, including light conditions and feed distribution. Testing and combining the technologies properly at full-scale provides good conditions for developing such solutions - at the same time as we see that there are still issues that should be better elucidated when it comes to adapting operations and technology to optimize good operation and environmental benefits," says Sinkaberg.

"If you also add a battery hybrid package, the feeding system in this feed barge provides significant environmental effects and cost savings in the aquaculture industry. Only a monthly cost saving of around NOK 200,000 in generator operation for feeding ten pens provides a good reason to take a closer look at this feeding technology," says Hans-Øyvind Sagen, Sales Director AKVA group Nordic.

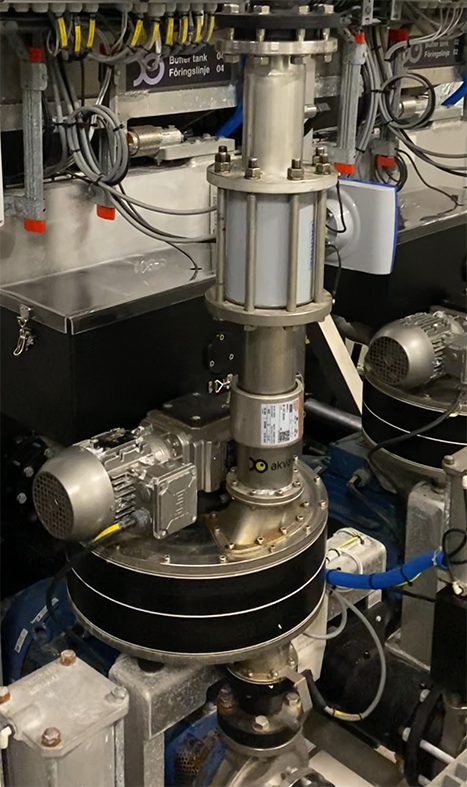

IMAGE CAPTION: The gate valve is an important component in the waterborne feeding system. The construction is based on the experiences from the last time AKVA group developed waterborne systems in 1980-1990.

Stable operation

New technology is always associated with both costs and some uncertainty. To adapt the feed barge and gain useful experiences with the new technology, SinkabergHansen entered into a lease agreement for the AC 600 VR feed barge from late autumn 2019.

"We have great respect and are very grateful for that SinkabergHansen took on the task of being in the front line with us to work out waterborne feeding technology," says Sagen.

Early in spring 2020, the feed barge and waterborne feeding operation were stable and the fish were harvested as planned in June.

"The largest bottleneck for introducing this new environmentally-friendly and cost-saving technology in the market is to show that the waterborne feeding system is stable in operation and provides at least the same growth rate as airborne feeding. In this context, this feed barge sale to SinkabergHansen, and the collaboration with them, is very important for further market development," says Sagen, who also sees opportunities for existing feed barges.

"In the short term, existing feed barges can be rebuilt from airborne feeding to waterborne feeding, as the energy and environmental effect will be the same as waterborne feeding for new feed barges. In Norway alone, there are several hundred feed barges of steel and concrete that may be relevant for such a rebuild, and it will provide enormous energy savings and environmental effects," says Sagen.

Feed Barge AC 600 VR

|

Feed Barge: |

Capacity: |

Feeding System: |

|

Length: 44,45m Width: 12m Below waterline at

Hs: ≥6m |

Load capacity

Among others:

|

|

|

Environmental conditions Hs: ≥6m Vs: <2,5 m Tp: >15 sek

|

Battery/hybrid capacity 230kWh

|

|