Feed comprises 55–60% of fish farm costs. Every % you save on feed costs will have a massive impact on the bottom line. The potential savings easily justify investments in infrastructure.

Key figures for the aquaculture industry show that feed is the highest individual cost for the farmers, by a large margin. As much as 55–60% of costs relate to feed, while approximately 1% represents personnel and salaries. That may lead you to think that hiring more staff to assist with feeding is cost-effective.

I believe the better option is to invest in the skilled personnel already on your team.

A good learning environment

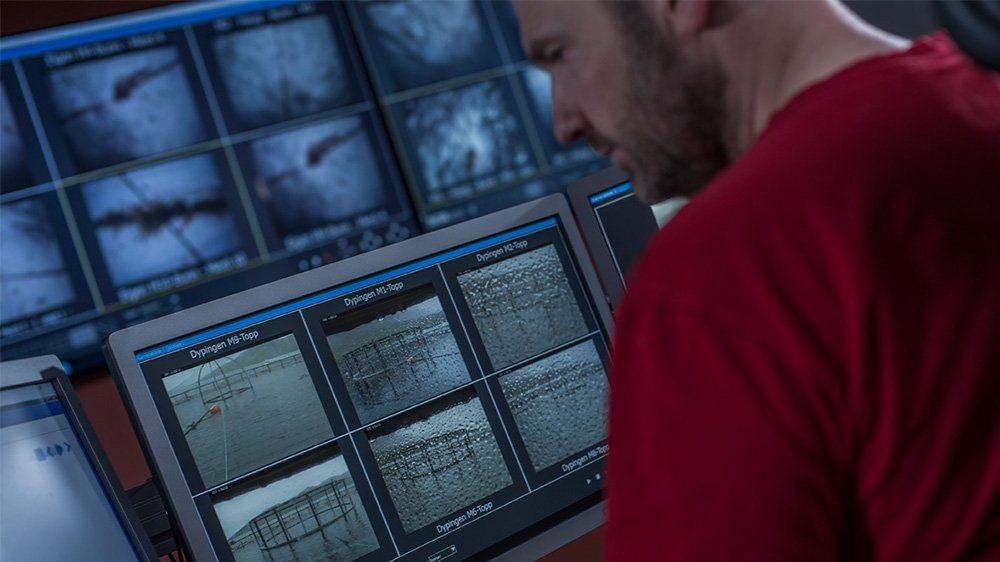

On most sites today, surveying pens is a one-man-operation, using cameras and sensors. However, running the operation of multiple sites from a central control room benefits your staff and creates a great learning environment. The best operators work closely with the less experienced ones in identifying the optimal start and stop levels for feeding. Proximity to other specialists, such as biologists and vets, ensures professional support and increased knowledge sharing.

Compared to the one-man-operation, the team will have a sounder basis for decision-making and develop more objective criteria for feeding.

Focus on feeding

Making everyday life at the pen run smoothly, the operator will occasionally be instructed to assist in solving particular tasks or sudden events. In a central feeding unit, operators will no longer be interrupted and can focus 100% on feeding. They will be in a much better position to optimize feeding, chasing the small increments in feed efficacy that immediately impact your profit.

You can also cut personnel costs considerably. A company with ten sites can reduce the number of operators on duty from ten to three.

Enabling more operators to collaborate will also reduce the risk of costly miscalculations.

Ready for industry 4.0

I don't wish to sound too pretentious when I claim that tomorrow's feeding technology is already here. Rapid development in artificial intelligence (AI) and machine learning is taking place as I write this.

AKVA group has established the AKVA Observe project and seeks to exploit AI and machine learning at fish farms. These hard trends are rapidly developing and will soon redefine the role of the operator. We face solutions that fully automate feeding. The operator will mainly monitor the process, focus on deviations, and make decisions supported by artificial intelligence.

Fish farms that have already invested in remote controlled feeding will be able to utilize this new technology from day one.

{{cta('5adf1d13-40b4-46b9-9102-315aa95343f2')}}